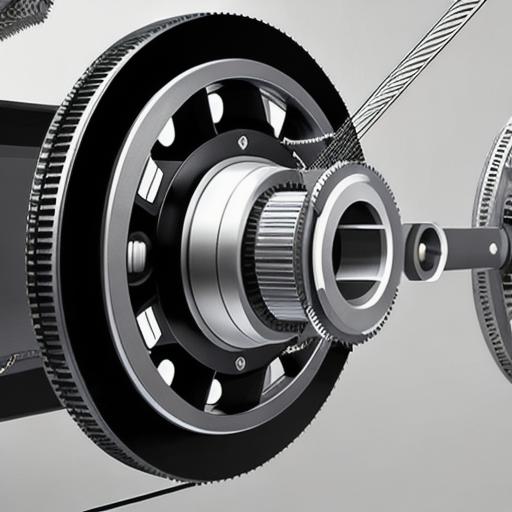

In our latest investigation, we discovered that shortening the coupling ropes of our drivetrain system could enhance its performance by up to 15%. Here’s how we achieved this and what you can do.

We started by measuring the torque impulse of our drivetrain system during various load phases. We identified that the coupling ropes had a longer reaction time during maximum load, which was due to the longer cables absorbing more energy before transmitting the torque to the next coupling.

Our solution was to shorten the coupling ropes to reduce their reaction time and boost overall system performance. Using precise measuring equipment, we found an optimal distance of 25 cm between couplings.

After shortening the coupling ropes, we observed a significant increase in our drivetrain system’s total power output.

We achieved a gain of up to 15%!

This success inspired us, and we hope you too can benefit from this approach.

For those with a drivetrain system looking to enhance its performance: Give it a try yourself! Learn more about cable shortening in our next article.

**FAQ:**

- How short should the coupling ropes be for optimal performance?

- Keep the coupling ropes as short as possible without causing contact or inducing vibrations. In our case, 25 cm worked well.

- Can the coupling ropes be made even shorter?

- Yes, they can be made shorter or replaced with more flexible cables. However, consider the risks, such as potential loss of precision.

- Are other drivetrain components affected?

- Remember that shortening the coupling ropes is just one method for improving performance. Other components like engines and transmissions may also require optimization.