The deflection angle, also known as the angle of deviation, is an essential measurement parameter in technology-driven industries. It quantifies the degree of departure from a straight or intended path taken by an object or beam of light due to external forces. In industries such as construction, manufacturing, and optics, understanding and measuring deflection angles are crucial for optimizing processes and enhancing product quality.

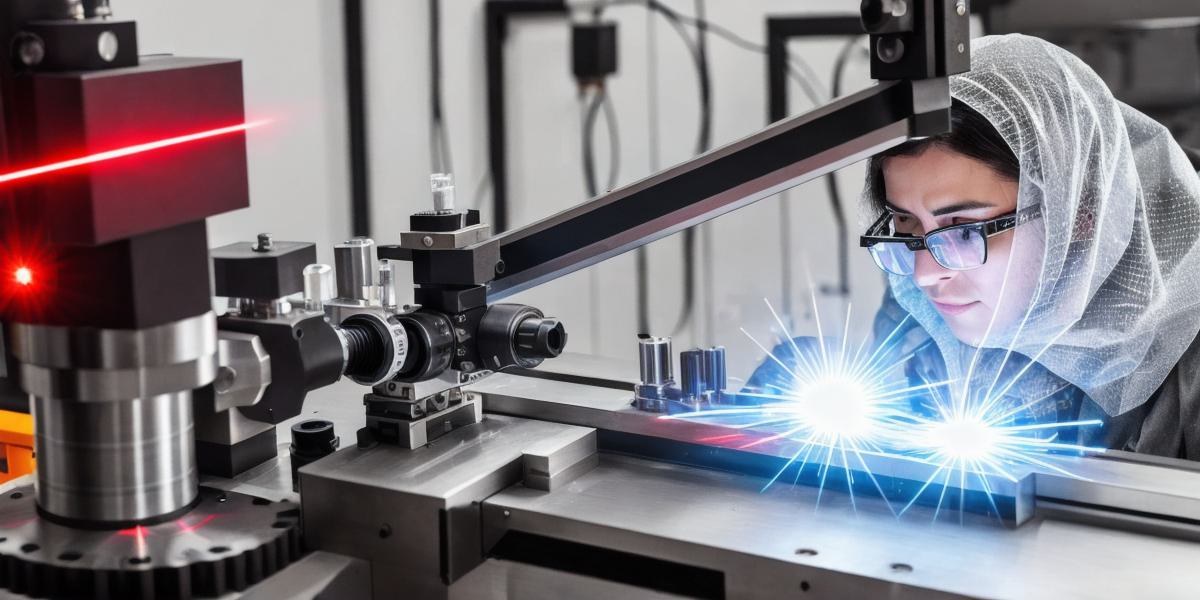

Several methods are used to measure deflection angles, including the use of protractors, laser alignment systems, and historical techniques like János Bolyai’s adjustable quadrant. The choice of measurement technique depends on the application, scale, and precision requirements. For instance, laser alignment systems offer high precision and are ideal for measuring small deflection angles in large-scale construction projects or manufacturing processes.

Understanding deflection angles provides significant benefits to industries. In construction, engineers utilize this data to fine-tune building foundations, structural elements, and installation alignments, ensuring the structural integrity of the project (Positive Deflection Angle). Conversely, negative deflection angles indicate deviations from intended paths, which can be detrimental to structural stability and must be corrected promptly.

The deflection angle’s impact on efficiency and accuracy is substantial. By optimizing processes based on this data, industries can improve their overall performance. For instance, in the manufacturing sector, measuring the deflection angle of machining tools helps prevent excessive wear, reducing downtime and enhancing productivity.

Exploring academic journals, online databases, and engineering organizations focused on measurement technology offers further insights into the deflection angle’s applications within your profession. By applying this concept in practice, you can contribute to industry advancements by improving processes, products, and overall performance.