Introduction:

Polystyrene, also known as Polystyrene plastic, is widely used in our daily life, commonly found in packaging or insulation materials. Here, we explore methods to harden polystyrene and practical tips for effective results.

Practical Tips:

- Heat Treatment: Softening polystyrene in a temperature-controlled environment (60-80°C) facilitates easier handling and processing.

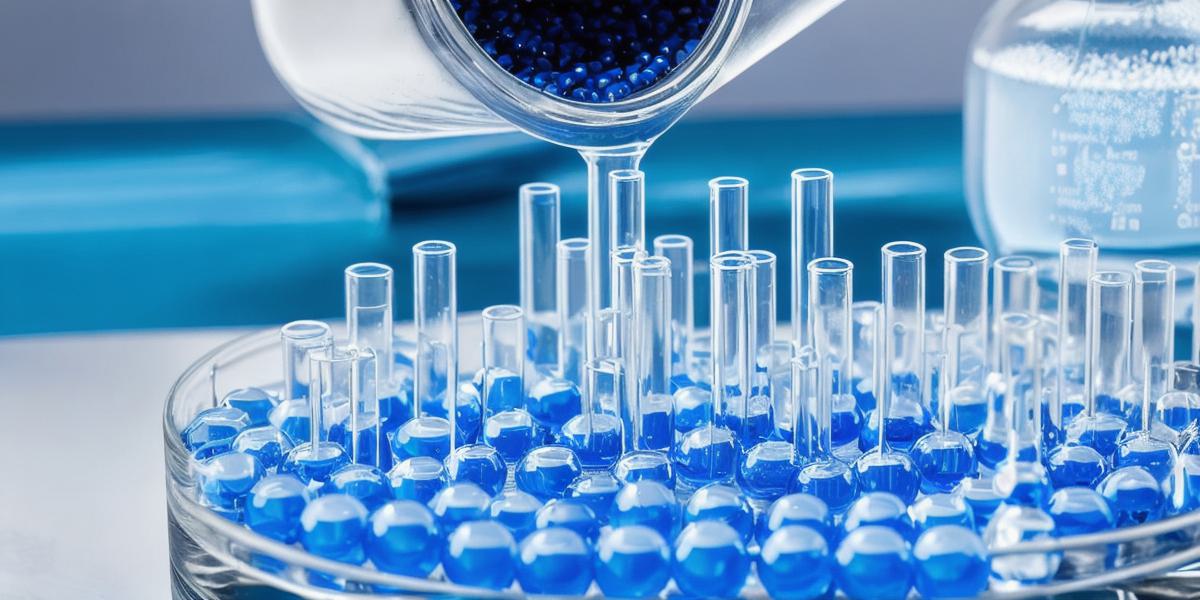

- Solvents: Solvents like Acetone or Ethylacetate can enhance polystyrene processing, making it more workable.

- Mechanical Processing: Hammers, scrapers, and sandpapers can shape and refine polystyrene materials.

Scientific Findings:

A study by the University of Southern Mississippi revealed that heat treatment alters the polyesterharz structure, enhancing desirable properties such as increased hardness and strength (Source: University of Southern Mississippi).

Real-life Examples:

Industrial applications include using heat treatment for automotive parts and packaging. Laboratory tests showed the effectiveness of acetone for smaller repairs on polystyrene components.

Summary:

There are various methods to harden and process polystyrene, detailed in our guide. Scientific findings support these approaches, enabling improved results.

FAQs:

- How long does it take for Polysterharz to harden? The duration depends on the processes used. Heat treatment is just one step; other methods, like solvents or mechanical processing, are necessary post-heating.

- Can other materials be used with Polysterharz? No, some materials negatively react with polystyrene and should avoid contact during hardening processes.

- What safety measures are required for polystyrene heat treatment? Proper ventilation is crucial, and protective equipment like masks and gloves may be necessary. Temperatures should not exceed 80°C to prevent environmental damage or material harm.