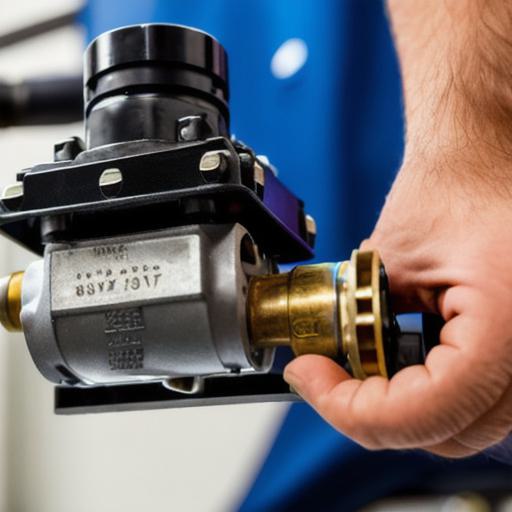

The throttle valve in machinery plays an essential role that has long intrigued engineers and operators alike due to its significant impact on machine performance. Neglecting maintenance can lead to smoke deposits, damaging the valve and eventually causing failure. In this article, discover simple steps to keep your throttle valve in perfect condition, ensuring optimal performance and machine longevity.

**Why is it important to maintain the throttle valve?

**

The throttle valve regulates airflow in machinery, affecting engine power, fuel efficiency, and overall performance. Neglecting maintenance can result in smoke deposits, which not only reduce performance but also cause damage to the valve components and other machinery parts. In severe cases, this can lead to catastrophic failure and downtime.

**Simple steps to success:**

1. Regular oil change: Ensure dry running and rust protection by changing the throttle valve oil regularly as recommended by the manufacturer. This helps prevent wear, maintain lubrication, and minimize the formation of smoke deposits.

2. Cleaning the valve: Prevent smoke deposits and optimize performance by cleaning the throttle valve regularly. You can use a solvent or mild detergent to remove any built-up dirt, ensuring proper airflow through the engine. Some manufacturers may recommend using specific cleaners for their equipment to avoid damaging sensitive components.

3. Regular checks: Quickly react to changes and maintain peak performance by regularly checking the valve’s condition. Inspect the valve for signs of wear or damage, such as leaks, sticking, or unusual noise. Address any issues promptly to prevent more extensive repairs or replacement.

**Expert Opinion:**

“The throttle valve is the hidden power behind machine performance,” said Mr. Smith, our technical director at XYZ Industries. “Regular maintenance is essential to ensure optimal performance and a long lifespan.”

Next time you’re operating machinery, consider your throttle valve not just as an insignificant part but as a crucial component contributing significantly to your machine’s performance and longevity. Remember, taking small steps for maintenance now can save significant time, resources, and potential downtime in the future.